Case-story: Amec Spie

4D VISION, EEN IDEALE PARTNER VOOR AMEC SPIE

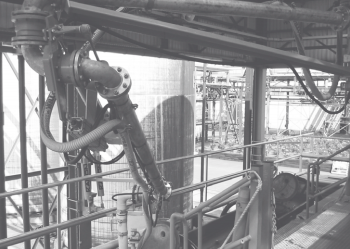

Onlangs realiseerde het industriële aannemingsbedrijf AMEC SPIE een belangrijk project in de petrochemische sector. De opdracht bestond erin de verlading van vrachtwagens op de fabrieksterreinen volledig te automatiseren. Met het LISA-concept (zie kadertekst) had AMEC SPIE de ideale bouwstenen in huis om de automatisering tot een goed einde te brengen. Samen met IT-partner 4D vision stelde AMEC SPIE een gebruiksvriendelijke en beheersbare totaaloplossing samen. En dat op korte termijn.

EXPERTISE EN SNELHEID HAND IN HAND

PROJECTEN MET EEN STRIKTE DEADLINE

Logistieke processen zijn cruciaal voor de dagelijkse werking van industriële bedrijven zoals Yara, Solvay, Arcelor, Atofina en Vos Logistics. Ze mogen zo min mogelijk stilliggen. De automatisering ervan moet daarom typisch op een korte termijn worden gerealiseerd. Dat weet ook AMEC SPIE, een ervaren elektromechanische aannemer in automatisering, grote infrastructuurwerken en industriële projecten. “Dankzij LISA beschikken we over een handige concept-tool om de eigenlijke automatisering snel uit te voeren”, vertelt Bernadette Lammens, projectmanager bij AMEC SPIE. “Vooraleer we daarmee starten, doen we een grondige analyse van de behoeften van de klant. Als die in kaart zijn, beschikken we over de juiste basis om tot implementatie over te gaan.” Tijdens de analysefase komen ook de beheersaspecten van het project aan bod. Om een automatisch verladingproces werkbaar te houden, moeten vrachtwagenchauffeurs op een eenvoudige manier doorheen heel het traject worden geloodst. “De beheersoftware is een kritische factor in het geautomatiseerde proces”, aldus Bernadette Lammens. “We werken dan ook graag samen met een flexibele IT-partner die snel een performante beheersoplossing op maat kan samenstellen. Zo garanderen we de klant een optimale totaaloplossing.”

DE FLEXIBILITEIT VAN EEN ERVAREN PARTNER

4D vision is een ideale IT-partner voor de LISA-projecten van AMEC SPIE. Bernadette Lammens vertelt waarom. “De medewerkers van 4D vision zijn thuis in heel wat softwaresystemen. Dankzij die brede IT-achtergrond kunnen ze LISA perfect op maat integreren in de specifieke omgeving van de klant, gaande van klanteigen software tot SAP. Zo kunnen ze bijvoorbeeld de volumecontracten in SAP de verlading laten sturen. Een klant die zijn maandelijkse afnamegrens al heeft bereikt, zal tijdens die maand dan niet meer kunnen laden.” Bovendien hebben de medewerkers van 4D vision al heel wat projecten op hun actief in verschillende sectoren. Vanuit die ervaring ontwikkelden ze een vaste projectmethodologie. Bernadette Lammens: “Dankzij die gestructureerde manier van werken, kunnen ze een project perfect managen. Ze weten hun tijd te plannen om binnen strikte deadlines een oplossing op maat te ontwikkelen.

JUISTE METHODOLOGIE EN TOOL VOOR SNELLE ONTWIKKELING

De 4D-methodologie van 4D vision eindigt met de implementatie van de ontwikkelde oplossing (deploy). Maar alles start met een uitgebreide analyse van de klantenbehoeften (define). Met die informatie tekenen de experts een oplossing uit op papier (design). In overleg met klant en partner werken ze die oplossing verder uit en beginnen ze met de eigenlijke ontwikkeling ervan (develop). Bij het project in de petrochemische sector kwam het er vooral op aan om het LISA-systeem met een performante beheersoplossing uit te rusten. De zelf ontwikkelde WebXTC-tool (Web eXtendable Transactional Components) was daarvoor het ideale instrument. Het laat immers toe om snel gebruiksvriendelijke browser-applicaties te ontwikkelen. Marc Haenebalcke, afgevaardigd bestuurder van 4D vision: “Met WebXTC slaagden we erin snel beheersprogramma’s te ontwikkelen die perfect zijn afgestemd op het LISA-systeem en de behoeften van de klant. Zo stelden we onder andere een programma samen waarmee vrachtwagenchauffeurs eenvoudig belangrijke gegevens zoals het transportnummer kunnen invoeren. Op basis daarvan weet het laadstation welke stoffen in welke hoeveelheid moeten worden ingeladen. De applicaties die we met WebXTC genereren gebruiken trouwens het Microsoft .NET-framework. Het is de meest geavanceerde en wijdverspreide technologie in het bedrijfsleven vandaag.”

TERUGVERDIEND IN MINDER DAN TWEE JAAR

Het automatiseringsproject bezorgde de klant een aanzienlijke besparing en had een ROI van minder dan twee jaar. “Samen met 4D vision slaagden we erin het volledige verladingproces te automatiseren. Nergens komt er nu nog een medewerker van de klant aan te pas: van de identificatie van de chauffeur over de eigenlijke verlading en het meegeven van het correcte CMR-document”, vertelt Bernadette Lammens. “Het systeem versterkt ook de concurrentiële positie van de onderneming. Klanten kunnen nu 24/24 en 7/7 komen laden, een belangrijke uitbreiding van de service.” Het gerealiseerde systeem kan bovendien perfect meegroeien met het bedrijf. Dat bevestigt ook Marc Haenebalcke: “Klanten krijgen vaak pas een concreet idee van de mogelijkheden van een systeem, nadat het is geïmplementeerd. Daar houden we uiteraard rekening mee. Het LISA-systeem is van nature uit een open systeem en dankzij WebXTC kunnen we ook in de beheersmodule snel nieuwe applicaties ontwikkelen die de nieuwe informatiebehoeften van de klant beantwoorden.”

De automatisering van logistieke processen met lisa levert belangrijke besparingen op. Daardoor hebben nieuwe lisa-projecten typisch een heel korte roi.

VLOTTE SAMENWERKING SMAAKT NAAR MEER

De eerste samenwerking tussen beide partijen heeft de synergie van het partnerschap al aangetoond. AMEC SPIE ziet 4D vision dan ook als een voorkeurpartner voor de toekomst. “De samenwerking met 4D vision verliep zeer vlot. Dankzij hun flexibiliteit, snelheid en ervaring kunnen ze binnen een beperkte tijdspanne een oplossing op maat ontwikkelen. We zien ze dan ook als een perfecte partner voor onze LISA-projecten en zullen er in de toekomst zeker nog mee samenwerken.”

LOGISTIEK GEAUTOMATISEERD LISA

staat voor Logistics Information System and Automation. Het softwaregebaseerde systeem omvat vier lagen: database, gebruiksvriendelijke user interfaces, tussenlaag voor integratie met perifere systemen zoals SAP, en automatiseringslaag met PLC’s voor sturing van de logistieke processen. AMEC SPIE ontwikkelde het LISA-systeem onder meer om vrachtwagens op een fabrieksterrein automatisch te laden en te lossen, rekening houdend met ADR-specificaties. Maar ook de voorbereidende, gelijktijdige en afsluitende acties worden ermee geautomatiseerd. Documenten zoals laad- en losbrief worden volledig automatisch voorbereid. Ook het afwegen van vrachtwagen en product tijdens het laden gebeurt automatisch, net als de nabehandeling. Zo past het systeem bijvoorbeeld de factuur aan op basis van de eigenlijke verlading.